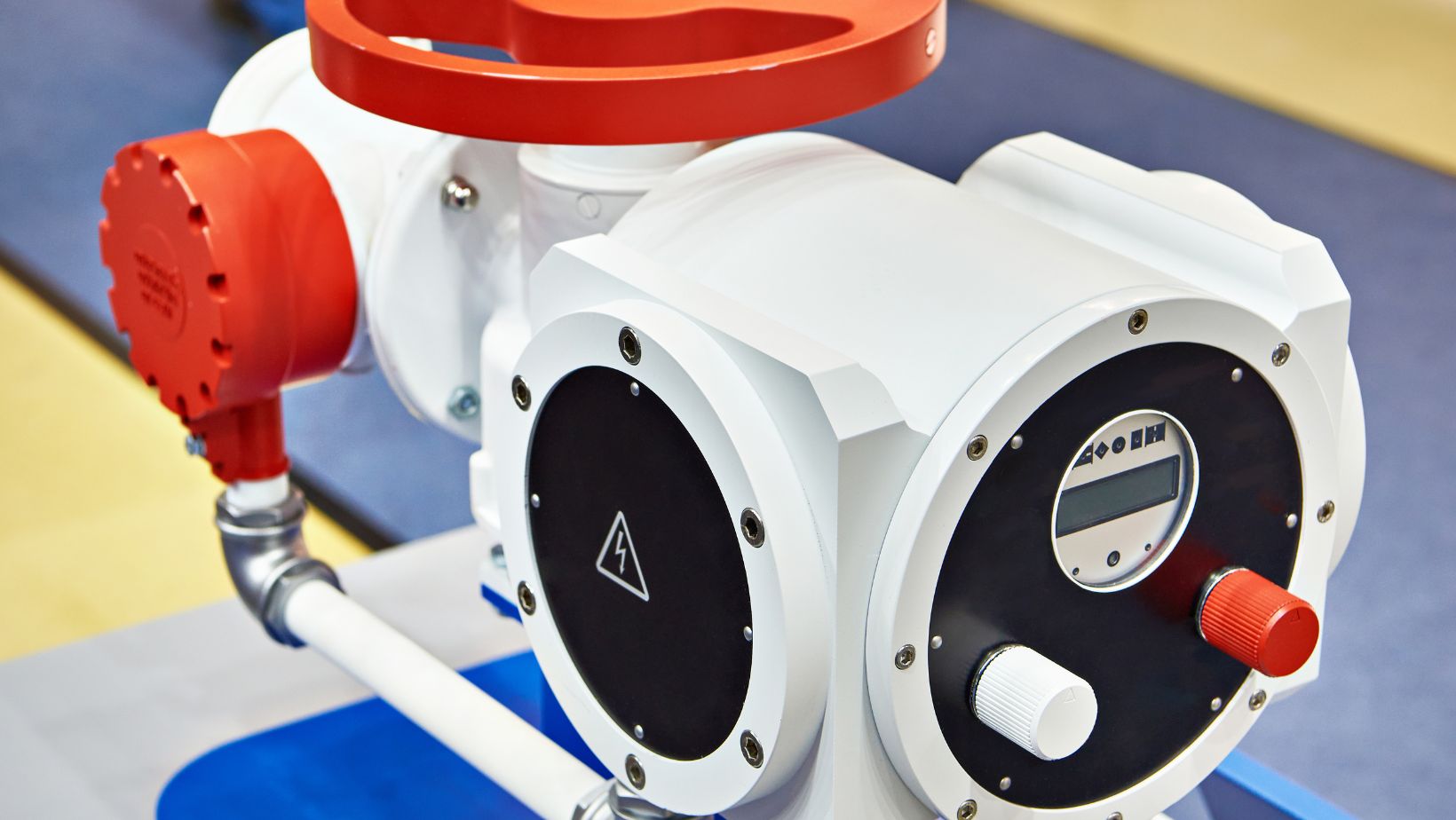

One innovative solution that has gained significant attention in the manufacturing industry is the rotary actuator, a versatile device that plays a crucial role in various applications. This article delves into the ways actuators can contribute to environmental sustainability, highlighting their benefits and the potential impact on our ecological footprint.

In other words, environmental sustainability involves the responsible management of resources to reduce pollution, minimize waste, and lower energy consumption. Actuators, particularly electric actuators, have emerged as key players in promoting eco-friendly automation.

Leveraging Electric Actuators for Reduced Energy Consumption

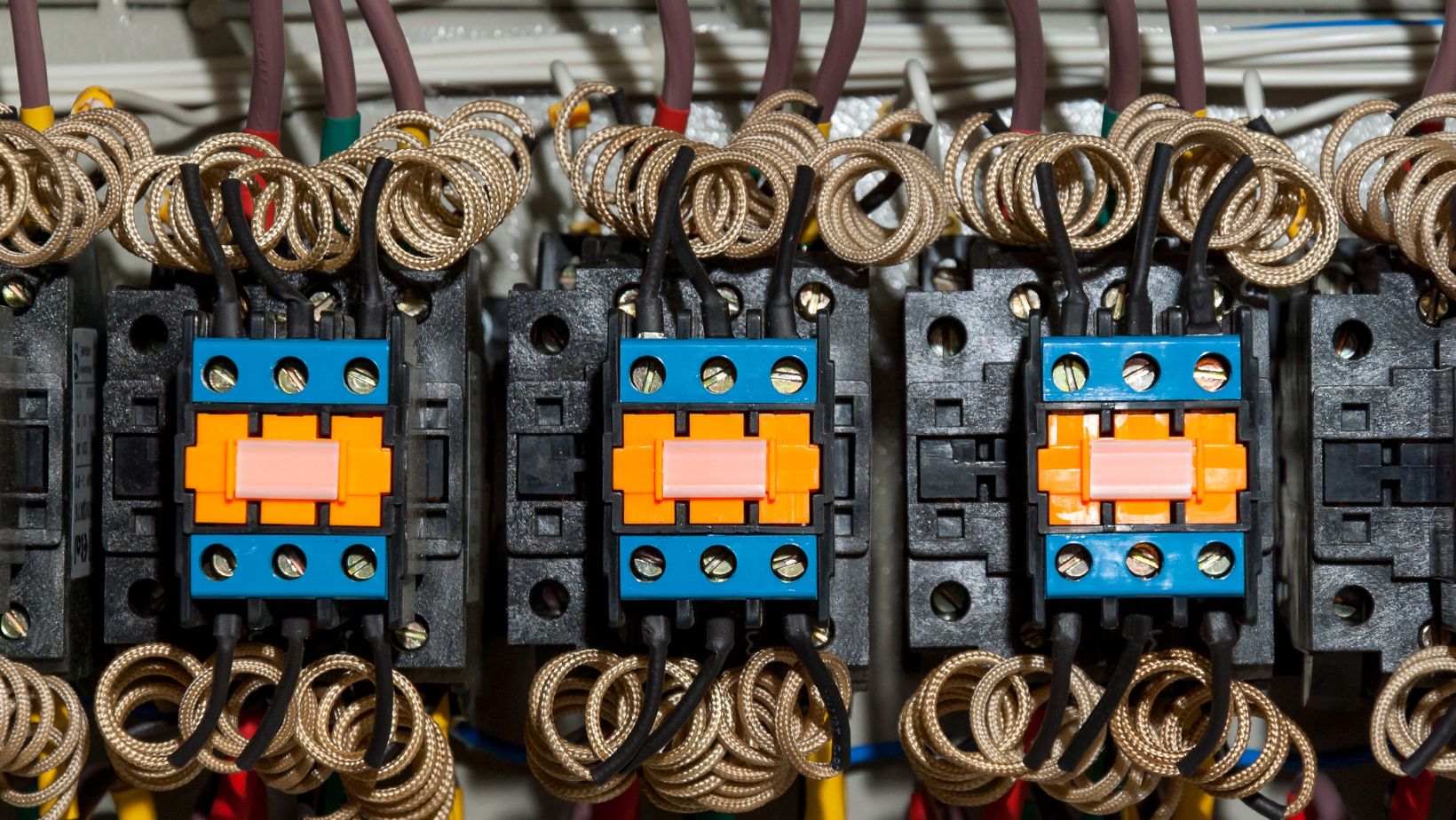

Electric actuators are known for their high energy efficiency compared to their hydraulic and pneumatic counterparts. They operate on electricity, which can be generated from renewable sources such as solar and wind power. This significantly reduces the carbon footprint associated with traditional energy sources. By integrating electric actuators into industrial processes, companies can achieve substantial energy savings, leading to lower operational costs and a positive environmental impact.

Electric actuators are designed to provide precise control, which means they can be used to optimize energy usage in various applications. For example, in HVAC systems, electric actuators can precisely regulate airflow and temperature, ensuring that energy is used only when needed. This precise control helps in reducing energy waste, thereby contributing to overall energy efficiency and sustainability.

Actuators in Reducing Methane and Other Greenhouse Gases

The use of actuators can significantly contribute to the reduction of greenhouse gas emissions, particularly methane. Methane is a potent greenhouse gas that has a more severe impact on global warming compared to carbon dioxide. Electric actuators can replace older, less efficient systems that are prone to leaks and emissions. By using electric actuators, industries can ensure tighter control over processes that generate methane, such as oil and gas extraction and processing.

The Environmental Protection Agency (EPA) has emphasized the importance of reducing methane emissions to combat climate change. Companies can comply with regulatory standards and reduce their environmental impact by adopting electric actuators. This not only helps in meeting environmental goals but also enhances the company’s reputation as a responsible and eco-friendly entity.

The Role of Actuators in Reducing Industrial Waste

Actuators contribute to waste reduction by enhancing the precision and control of industrial processes. Precise control means that raw materials are used more efficiently, reducing the amount of waste generated. For instance, electric actuators can ensure that materials are cut or shaped with exact measurements, minimizing scrap and wastage in manufacturing processes.

Furthermore, electric actuators do not require the use of hydraulic fluids or other potentially harmful substances that can lead to pollution. Hydraulic systems, in particular, are prone to leaks, which can contaminate the environment. By switching to electric actuators, companies can reduce the risk of spills and leaks, protecting the environment from harmful pollutants.

Automating Processes with Actuators for Better Resource Management

Automation is a key aspect of modern industry, and actuators play a crucial role in automating various processes. By automating repetitive and precise tasks, actuators help in improving efficiency and reduce human error. This leads to better resource management and less wastage of materials and energy.

For example, in water treatment plants, actuators can automate the opening and closing of valves, ensuring that water is treated efficiently and with minimal waste. Similarly, in agricultural applications, actuators can automate irrigation systems, ensuring that water is used efficiently and only when necessary. This not only conserves water but also reduces the energy required for irrigation, contributing to overall sustainability.

Integrating Actuators with Renewable Energy Technologies

Actuators are essential components in the operation and control of renewable energy systems. In wind turbines, actuators are used to adjust the blade pitch to optimize energy capture from the wind. In solar power systems, actuators can be used to adjust the angle of solar panels to maximize exposure to sunlight. By integrating actuators with renewable energy technologies, we can enhance the efficiency and reliability of these systems.

The use of actuators in renewable energy systems helps in reducing dependence on fossil fuels, thereby lowering greenhouse gas emissions. As renewable energy technologies continue to evolve, the role of actuators in ensuring their optimal performance becomes increasingly important. This not only helps in meeting environmental goals but also supports the transition to a more sustainable energy future.

Conclusion

Actuators play a vital role in helping industries meet their environmental goals. From improving energy efficiency to reducing greenhouse gas emissions, minimizing waste, enhancing automation, and supporting renewable energy systems, the benefits of actuators are multifaceted. By adopting electric actuators, companies can make significant strides toward sustainability, ensuring a healthier planet for future generations. Embracing these technologies not only helps in achieving regulatory compliance but also positions companies as leaders in environmental stewardship.